What is a Work Centre?

A Work Centre is the smallest unit at which Overall Equipment Effectiveness (OEE) is measured. It is typically a production line or cell, but it can also refer to an individual machine. Even when defined at the line or cell level.

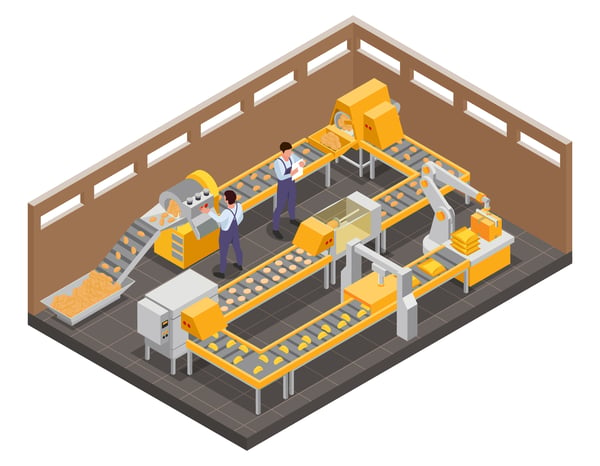

The image above represents a potato crisps production line, which consists of six key machines:

- Potato Washing and Peeling Machine → Processes raw, unclean potatoes

- Blanching Machine → Cleans and preps raw potatoes

- Potato Slicer → Cuts potatoes into thin slices

- Frying Machine → Cooks slices into crisps

- Packing Machine → Packages crisps into individual packs

- Case Packer → Packs three individual crisp packs into a carton

OEE tracking can be conducted at different levels to optimize production efficiency:

-

Full Line Performance:

- By placing a counter at the bottleneck, the slowest stage of production, we can measure how many crisps are produced per minute.

-

Individual Equipment Performance:

- Example: Tracking how often the Potato Slicer gets jammed and how long production stops due to these jams.

-

Final Product Output:

- By placing a counter at the end of the line, we can track how many individual packs of crisps are produced.

-

Intermediate Product Tracking:

- Counting how many individual crisps are produced at the Frying Machine stage.

-

Rejects & Waste Monitoring:

- Measuring how many potatoes or crisps are rejected and how much waste is generated during production.

Summary

OEE allows manufacturers to track and analyze production efficiency at various levels, from the entire production line to individual machines. By strategically placing counters and monitoring rejects, businesses can identify bottlenecks, inefficiencies, and quality issues, ultimately improving overall productivity and reducing waste.

Read more: How do I create a Work centre?